[ad_1]

I’ll be trustworthy, rebuilding the wheels on our 1975 Honda CB550F was a job I hoped to place off lots longer. The method of lacing and truing wheels is tedious, and there are many alternatives to scratch a contemporary rim whenever you pull the tire irons out. Contemplating a shoestring finances is the cornerstone of our everyman CB550 tracker construct, and our inventory wheels are fully roached, I’ll be DIYing this complete course of on your training and commentary. Buckle up, as a result of we’ve some critical floor to cowl.

In Part 3 of our Honda CB550 tracker build, we began getting a few of our main visible modifications mocked up, however there was no seeing previous our trashed wheels. Moreover, we actually wanted our gnarly Bridgestone BATTLAX AX41 tires mounted to visualise the remainder of the challenge.

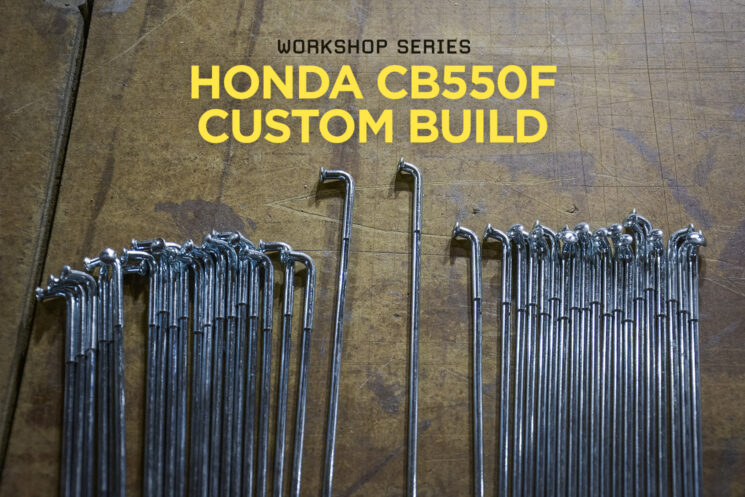

We’re solely salvaging the inventory hubs, so we ordered a fundamental wheel rebuild equipment with aluminum rims and zinc-plated spokes and nipples for proper round $170. Meaning the one disassembly concerned is taking an angle grinder to the unique spokes to liberate the hubs. I used a brass wire wheel on an air software to take away the corrosion and the outdated Honda clear coat, and buffed the hubs to a mediocre end with a sprucing wheel.

Lacing Motorbike Wheels I haven’t constructed sufficient wheels to contemplate myself professional, and even superior for that matter, but it surely’s not all that sophisticated if you happen to take your time and do your homework. Earlier than you chop up your outdated wheels, take a couple of measurements to find out if the hubs are offset to at least one facet, and a few photographs will assist set up reference factors for lacing spokes.

Lacing our Honda CB550F wheels begins with our interior spokes (the spokes with lower than a 90-degree bend) and the valve stem gap as our start line. We recognized its corresponding gap within the hub earlier than we began, however there’s loads of data on the internet if you happen to’re ranging from scratch. Utilizing our entrance wheel for example, you may see the bench rule types a tangent line from our first gap within the rim to its gap within the hub.

From there, observe the sample of holes within the hub and rim (skip one gap within the hub and three within the rim for our entrance wheel), and the interior spokes fall into place. Thread every nipple on just some turns to maintain the whole lot unfastened, and also you’ll wish to use some type of lube on the spoke threads in order that they tighten up constantly with out galling.

Subsequent, we flipped the wheel and used the identical sample for the interior spokes on the opposite facet, however lacing in the wrong way so the interior spokes cross one another. With interior spokes executed, the outer spokes are put in from the alternative facet of the hub and also you’ll have the ability to inform proper the place they go. Our outer spokes lace the wrong way of the inners, and the spokes cross 3 times on our entrance wheel, and two instances on the rear wheel.

Truing Motorbike Wheels We’ve got each wheels loosely assembled at this level, and it’s time to make them tight and true. A truing stand simplifies this course of a terrific deal, and ours is nothing greater than a finances unit from Harbor Freight. It will get the job executed, however (hilariously) doesn’t include a pointer, so we’ll use a dial indicator on a magnetic base with out being too choosy in regards to the precise measured values. If you happen to’re actually balling on a finances, you may true your wheels on the bike utilizing your axle as a fixture and a cable tie or another piece of scrap as a pointer.

Together with your wheel within the fixture of your selecting, it’s time to begin tightening up the nipples, however take it sluggish. Working the nipples down slowly and EVENLY will make the true enterprise of truing the wheel lots simpler, and the wheel will begin to take form whenever you’re all the way down to the final couple of threads.

Because the spokes begin seating within the rim, we will escape our pointer and begin fine-tuning the wheel. I like to begin with wheel hop, or up and down variance, to make sure we’re not too far out of whack proper off the bat. Tighten a sequence of interior and outer spokes to convey the rim up (nearer to the hub), and you might have to loosen some on the alternative facet to get issues into form. Addressing runout, or side-to-side variance, is completed similarly, besides you’ll tighten or loosen spokes on one facet of the wheel to shift it proper or left.

I went backwards and forwards with our CB550 wheels, checking the hop and runout, and making small changes of 1 / 4 flip at a time. It’s useful to make some reference marks with tape that will help you preserve observe of your downside areas. The larger the part that’s out of whack, the extra spokes you’ll have to regulate, however you’re all the time working a number of spokes to appropriate a piece.

As soon as the wheel is straightened out (and any hub offset accounted for), you wish to ensure that your spokes are tight, however not too tight—as you’ll gall up the threads on the spoke if you happen to go too far. There’s a specified torque on your spokes, however except you’ve gotten an adaptor and an inch-pound wrench, you’ll most likely use the audible torque spec technique. Knock an 8 mm wrench towards every spoke and hear for a pleasant ‘ping’ sound. A unfastened spoke will give a boring tone.

Perfection is the enemy of the great, as I spent manner an excessive amount of time straightening out our cheapo aluminum hoops. You’ll all the time have a hiccup in your measurements on the seam the place the wheel is welded collectively, and keep in mind to decorate any spokes protruding by means of the nipples earlier than putting in your rim strips.

Mounting Motorbike Tires We’ve come an extended solution to get our CB on some new rubber, and if you happen to’re nonetheless with me, I promise I’ll preserve this transient to get us over the end line. We’ve been teasing that we’ve some gnarly meats for our tracker challenge from the get-go, and it’s lastly time to put in our new BATTLAX ADVENTURECROSS AX41 tires from our mates at Bridgestone. They’re beefy and rad sufficient to ruffle some feathers, however we additionally appreciated the combination of DOT road and off-road efficiency the tire provides, and we had been stoked to seek out sizing choices that will work on our outdated CB550F.

If you happen to journey bikes, you’ve most likely modified a tire (or at the very least perceive the method), so I received’t beat this one into the bottom. Line up the balancing mark in your tire (if it has one) along with your valve stem and work the primary bead over. Soapy water and child powder are your folks right here. Then set up the tube and work your second bead on along with your trusty tire irons, ensuring to not pinch the tube within the course of.

We mounted our entrance tire by the e book, however I did it a second time to indicate a trick utilizing cable ties (as a result of I clearly wouldn’t mount the tire backward and need to redo it). With this hack, you put in the tube into the tire after which use a number of cable ties to squish each beads collectively. Primarily, you solely need to work the bead over the rim as soon as with this strategy, earlier than reducing and pulling the cable ties.

Postscript Ending that challenge, and condensing it for this website, requires a deep breath and a chilly drink. It’s not all that troublesome if you happen to’re headstrong and useful, and definitely value it if you happen to can take pleasure in a pair easy items of aluminum like I can. For the small dimension of our funding, the transformation is large, though I nonetheless have to redo the brakes and polish a couple of extra items.

With our new wheels and tires on the bike, I can lastly see the whole lot coming collectively and fine-tune the visible weight of our Honda CB tracker. It’s PLAINLY apparent the entrance fender doesn’t work as is, and I’ll do some mock-ups with the fender shortened, raised to the decrease tree and eliminated fully, however we’ll save that for an additional day.

Even with a contemporary tread design, I’m stoked on the tires. The bike appears timeless and rugged with a bit of early ’60s filth bike affect, and I can’t wait to hoon this factor round when it’s completed—that’s what it’s all about proper? I might ramble on, however there’s work to do. Time to tidy up our body extra and set up some suspension to match these meats. Keep tuned.

Bike EXIF thanks Motogadget, Tuffside, Bridgestone, Lowbrow Customs and Biltwell Inc. for supporting our Honda CB550F tracker construct.

[ad_2]

this Article is Supply FromSource link